Rombus Grid V1

Rombus Grid is a modular, flexible concrete system that replaces the need for traditional full-depth concrete slabs.

- Supports up to 10,000 tonnes per m²

- Only 40mm of concrete required

- Up to 60% cost savings on concrete and installation

- Fast install with only 1m³ of concrete for every 25m²

- No deep excavation or foundations required

- Minimal to no formwork, steel mesh or pump trucks

- Made from 100% Australian recycled plastic, cuts CO₂ emissions

- 100% Australian designed, owned and manufactured

Calculate your Rombus estimate

Enter your work area, select a Rombus product, and we’ll calculate approximate costings to supply Rombus product, excluding delivery, concrete and labour.

Your instant estimate

OPTION 1 – ROMBUS GRID (V1)

OPTION 2 – ROMBUS FUSION (V2)

Freight delivery quote

Complete the form below and we’ll reply within 24 hours.

Rombus vs Traditional Slab – Quick Comparison

Enter your work area and we’ll estimate a Rombus solution beside a 100–350 mm slab using industry average allowances.

Step 1 – Input your work area (either L × W or total area in m²)

Comparison

| Item | Rombus | Traditional slab |

|---|

Indicative supply-only comparison based on default allowances.

140%

Quicker installs

33%

Less Labour

Rombus Installation

How it works

Step 1

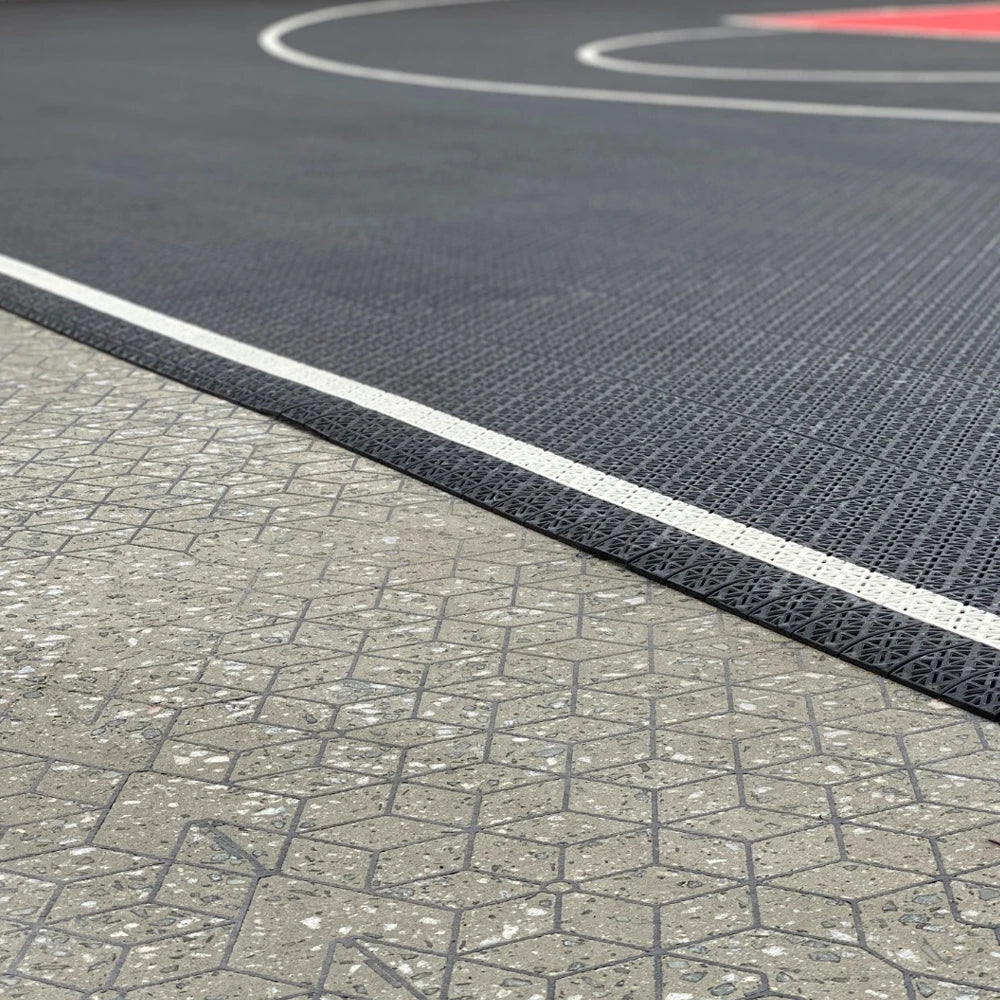

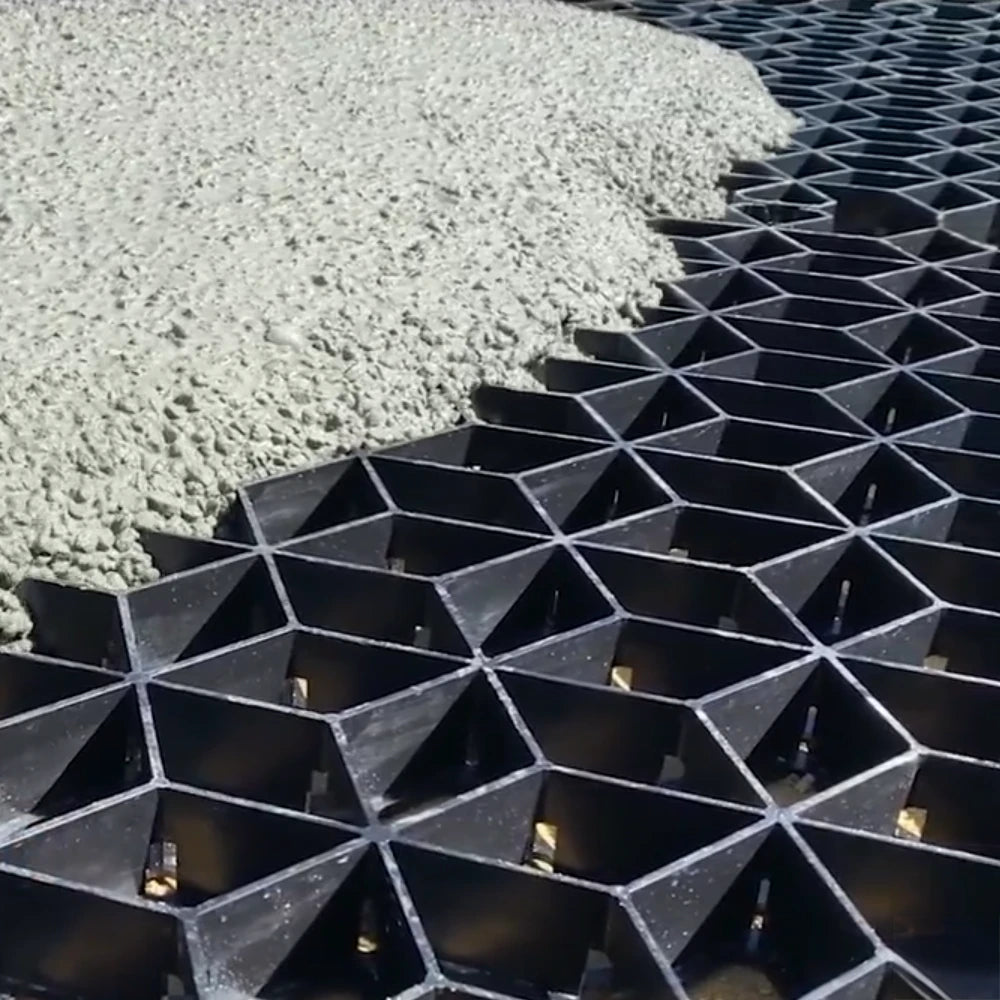

Lay the Rombus Grid onto a level surface

Step 2

Pour the concrete over the grid

Step 3

Use a vibrator to settle the concrete evenly with the top of the grid

Step 4

Trowel down the surface until you can see each and every individual cell

Rombus Features

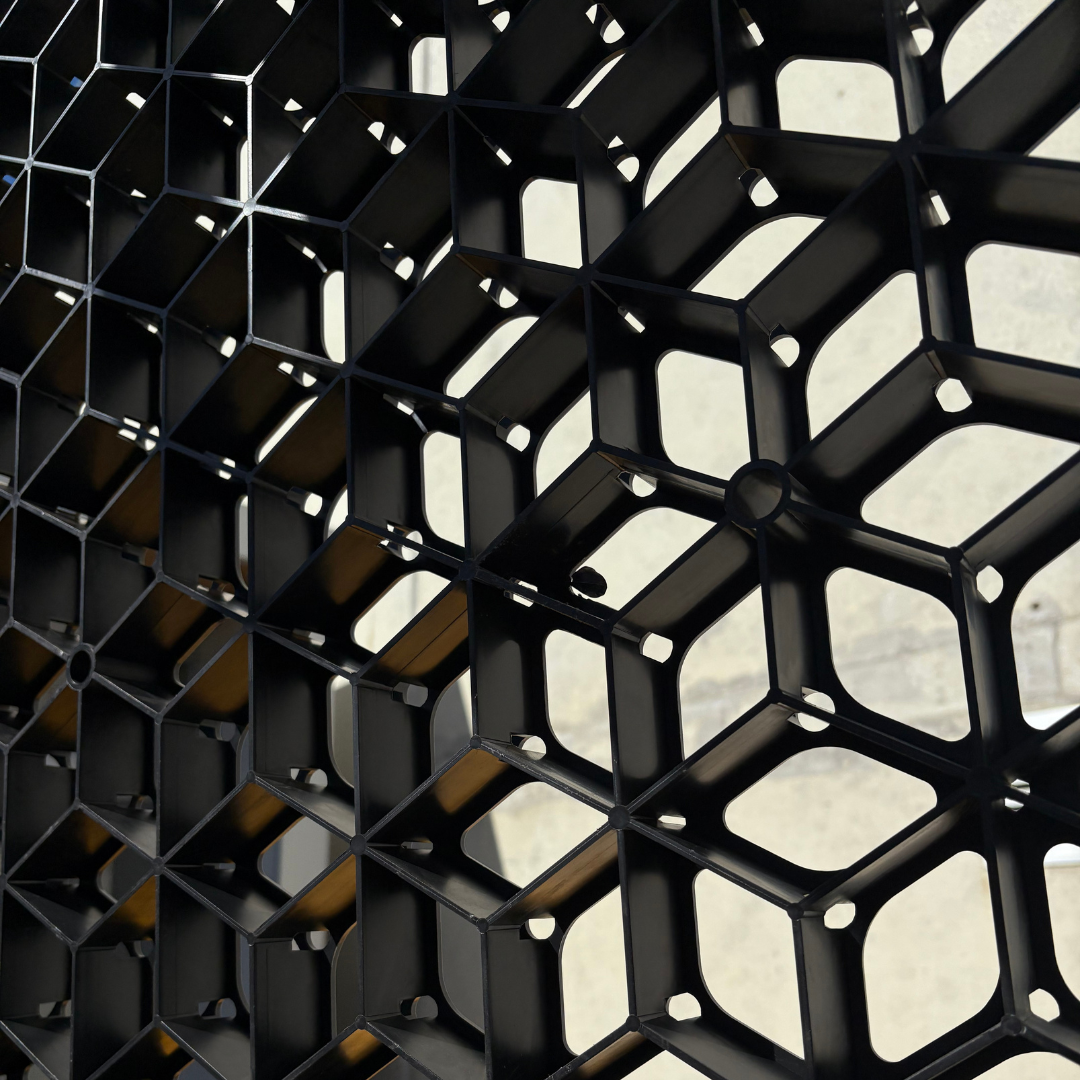

ENGINEERED STRENGTH

Exceptional load capacity

Handles up to 10,900 tonnes per m² when filled with concrete.

Modular, flexible concrete

Outlasts and outperforms traditional concrete and asphalt systems.

Innovative grid-cell structure

A revolutionary modular design that delivers durable, dust-free, and gravel-free surfaces for industrial environments.

Rombus Grid Features

EFFICIENCY AT EVERY STAGE

Faster installs

Versatile grid system installs up to 40% faster and requires 30% less labour.

Fewer deliveries, less material

40mm profile height significantly reduces concrete volume compared to conventional slabs.

Minimal downtime

Achieves full strength up to 75% faster than a 120mm traditional slab, allowing earlier access and reduced program delays.

Rombus Grid Features

ENGINEERED SUSTAINABILITY

Reduced carbon footprint

Low-profile 40mm design cuts embodied carbon by reducing concrete consumption across every installation.

Recycled materials

Each square metre of Rombus incorporates 5.4kg of 100% responsibly sourced recycled plastic, diverting waste from landfill.

Engineered for diverse sectors

Suitable for mining, construction, agriculture, storage, landscaping, and public infrastructure.

"I can't recommend Rombus enough! These guys did an amazing job within tight constraints, and the end product looks so unique and fantastic"

Compare Rombus Solutions

1000 x 1000 x 40mm (w x h x d)

1166 x 1166 x 48mm (w x h x d)

5.4kg per sheet

6.1kg per sheet

1m²

1.36m²

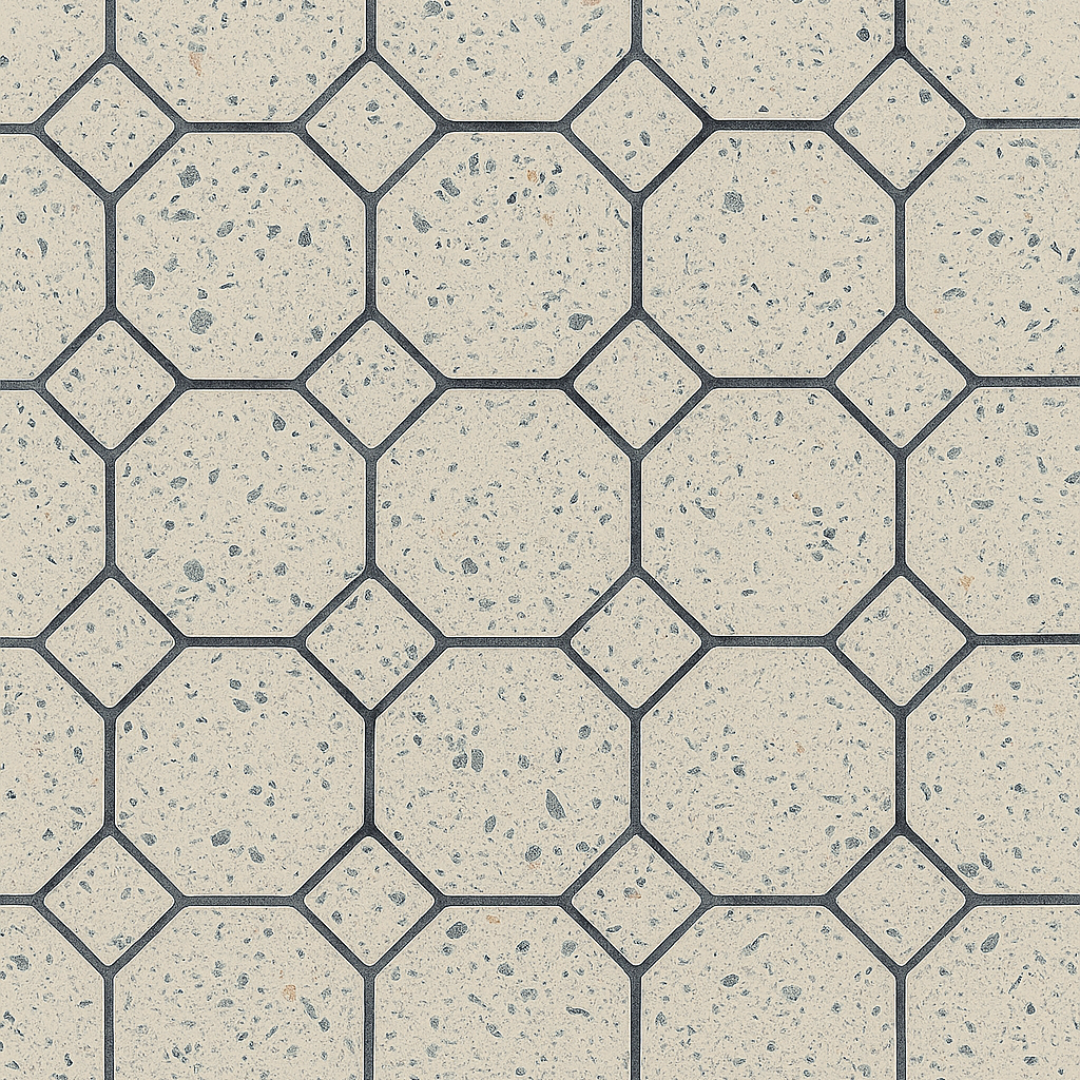

Diamond

Hexagon

Yes. Expansion joints every 20 m² to ensure stability and long-term performance

No. Overlap joins so no edging required

Fast efficient installs without compromising strength or durability

Stronger, smoother and designed for heavier loads

Case Study

Rio Tinto Hope Downs 4 Rio Tinto Mine

Rio Tinto’s Hope Downs 4 Mine - Warehouse needed a sealed, dust-free floor, but extensive slab damage and an unstable subgrade initially pointed to a full demolition and rebuild as the only viable solution. Rhombus provided a saving ~$480,000 and 127 tonnes of CO₂ emissions while reducing downtime by 20 days.

Frequently asked questions

Got a question? We're here to help.

What is Rombus?

An Australian-made modular pavement system that replaces traditional concrete slabs. Lightweight, flexible, and strong enough to handle 10,000+ Tonnes per m².

How does it work?

Rombus grids interlock and are filled with 4-4.8mm of concrete, creating a high-strength, low-thickness slab that installs quickly and performs for decades.

Where is Rombus made?

Rombus is manufactured in Australia from 100% recycled polypropylene.

What are the main benefits?

The system uses up to 90% less concrete, making it faster to install, more sustainable, and far better for the environment. The interlocking grids mean minimal downtime and long-term durability, built to last.

What’s the difference between Rombus Grid (V1) & Fusion (V2)?

Rombus Grid: 1000mm X 1000mm X 40mm, diamond-pattern, edging required, and expansion joints every 20 m² to ensure stability and long-term performance. Weight: 5.4kg Gross area per sheet: 1m2

Fusion V2: 1166 X 1166m X 48mm, hexagon pattern, overlaps so no joins or edging required. Weight: 6.1kg Gross area per sheet: 1.36m2

Has it been proven in the field?

Rio Tinto’s Hope Downs 4 Mine - Warehouse needed a sealed, dust-free floor, but extensive slab damage and an unstable subgrade initially pointed to a full demolition and rebuild as the only viable solution. Rhombus provided a saving ~$480,000 and 127 tonnes of CO₂ emissions while reducing downtime by 20 days. Link to case study

Aurizon’s Kalgoorlie Container Terminal - Rombus replaced damaged concrete with a fast, modular system that saved $350,000, cut over 172,000 kg of CO₂, and had the site operational again within seven days. Link to case study

Can you cut Rombus around obstacles?

Yes Rombus works great for navigating around obstacles and creating a seamless look

Contact Us